The clatter of misplaced wrenches, the frantic search for that one specific screwdriver, the cluttered bench that turns a simple project into an archaeological dig—we’ve all been there. Tool chaos isn’t just frustrating; it’s a productivity killer that transforms your workshop from a haven of creation into a stress-inducing maze. Enter the modern grid panel system: the evolutionary leap from flimsy pegboard that promises to revolutionize how you store, display, and access your tools. These customizable workhorses don’t just organize your space; they transform it into an efficient, visually intuitive command center where every tool has its place and every place serves a purpose.

But not all grid panels are created equal. The difference between a system that serves you for decades and one that buckles under pressure lies in understanding the nuanced features that matter most. Whether you’re outfitting a professional automotive shop, a serious woodworking studio, or a home garage that demands serious functionality, making an informed decision requires diving deep into materials, mounting options, weight dynamics, and accessory ecosystems. This comprehensive guide walks you through everything you need to know to select grid panels that don’t just hold your tools, but elevate your entire workflow.

Top 10 Grid Panels for Customizable Tool Display

Detailed Product Reviews

1. Grid Wall Panels, Grid Wall with Wheels,4x5.5Ft Gridwall Panel Display Stand,Sturdy Art Display Panels, Grid Display Stand, Black

Overview: This commercial-grade mobile gridwall system offers a robust solution for retailers, event vendors, and homeowners seeking versatile display options. Standing 63 inches tall and 48 inches wide, this self-supported unit eliminates wall-mounting requirements while providing substantial display real estate. The black powder-coated steel construction delivers a sleek, professional aesthetic suitable for high-traffic environments.

What Makes It Stand Out: The combination of oversized dimensions and heavy-duty mobility sets this unit apart. Four smooth-rolling casters (two locking) provide true portability for pop-up displays or dynamic space reconfiguration. The 2-inch grid pattern accommodates standard gridwall accessories, while the 24-inch depth creates a stable base that prevents tipping even when fully loaded. This is a true workhorse designed for commercial demands.

Value for Money: At $169.99, this panel sits in the mid-range for professional display equipment. Comparable wall-mounted systems often cost more when factoring in installation, while flimsier alternatives can’t match its 63-inch height and stability. For businesses requiring frequent layout changes, the mobility alone justifies the price premium over stationary units. Home users with serious organization needs will find it a one-time investment that outlasts cheaper alternatives.

Strengths and Weaknesses: Strengths include exceptional stability, commercial-grade steel construction, smooth mobility, and versatile applications from retail to garage organization. The locking wheels provide security on uneven floors. Weaknesses are the premium price point, lack of included accessories (hooks/shelves sold separately), and substantial footprint that may overwhelm small spaces. The 63-inch height, while advantageous, can make it challenging to transport in compact vehicles.

Bottom Line: This black gridwall panel excels for professional users who prioritize durability and mobility. While the initial investment is significant and accessories add to the cost, its commercial construction and versatile design make it ideal for serious retailers, frequent event vendors, or homeowners needing a permanent yet movable organizational solution. For temporary or light-duty needs, consider more affordable foldable options.

2. koretech Grid Wall Panels with Wheels, 4 x 5.5Ft Gridwall Panel Display Stand, Sturdy Art Display Panels, Grid Display Stand, White

Overview: Functionally identical to its black counterpart, this white version of the 4x5.5Ft mobile gridwall system offers the same commercial-grade construction and generous dimensions. The crisp white powder-coated finish provides an alternative aesthetic that brightens spaces and makes product colors pop. At 48 inches wide and 63 inches tall, it serves retailers, event vendors, and homeowners seeking a clean, modern display solution without permanent installation.

What Makes It Stand Out: Beyond the color difference, this unit shares the same standout features: heavy-duty steel frame, four smooth-rolling casters with locking mechanisms, and a versatile 2-inch grid pattern. The white finish particularly suits boutiques, art galleries, and contemporary home interiors where a lighter palette is preferred. The self-supporting design maintains stability while offering true mobility for dynamic display needs.

Value for Money: Priced identically at $169.99, the value proposition mirrors the black model. The choice between colors is purely aesthetic and environment-dependent. White may require more frequent cleaning in high-traffic or industrial settings but excels in retail environments where it creates a premium, gallery-like backdrop. The investment remains justified for professional users who need reliable mobility and durability.

Strengths and Weaknesses: Strengths include the same robust construction, excellent mobility, and versatile applications as the black version, with the added benefit of a bright, clean aesthetic. White surfaces can make small spaces feel larger and showcase colorful merchandise more effectively. Weaknesses include the premium price, absence of accessories, and the practical reality that white finishes show scuffs and dirt more readily than black, requiring more maintenance in rugged environments.

Bottom Line: Choose this white gridwall when aesthetics are paramount. It delivers identical performance to the black model but suits different design schemes. For retail boutiques, craft studios, or modern homes, the white finish justifies the same investment. However, for garages, warehouses, or heavy-use environments, the black version may prove more practical long-term.

3. DEMEGA Grid Wall Panels Foldable Gridwall Panel Display Stand Art Show Display Panels for Vendor Events Craft Shows Merch Display

Overview: This foldable gridwall system from DEMEGA offers a portable, budget-friendly alternative to fixed display units. Comprising four connected panels that unfold to 55 x 59.8 inches, it provides versatile configurations without tools or wall mounting. Designed specifically for craft shows, vendor events, and temporary displays, it balances functionality with portability for mobile entrepreneurs and occasional users.

What Makes It Stand Out: The innovative folding design allows multiple configurations—W-shaped, straight, or rectangular—adapting to different booth layouts and space constraints. The unit arrives fully assembled and includes detachable feet for stability. Its ability to separate into four wall-mountable panels adds long-term versatility, transitioning from event use to permanent home or studio organization.

Value for Money: At $99.99, this represents excellent value for occasional vendors and DIY organizers. The foldable design eliminates storage headaches, while the included feet and hinge system provide functionality that more expensive units lack. While its 80-pound capacity is less than commercial fixed units, it’s sufficient for most craft show merchandise and home organization needs, making it a smart mid-range investment.

Strengths and Weaknesses: Strengths include true portability, versatile configurations, no-assembly setup, and dual-purpose design for both freestanding and wall-mounted use. The foldable nature makes storage and transport effortless. Weaknesses include lower weight capacity than fixed units, potential stability concerns in high-traffic areas, and less polished aesthetics compared to premium models. The hinge system may wear with extremely heavy use over time.

Bottom Line: This DEMEGA gridwall excels for mobile vendors and event organizers who prioritize portability and versatility over maximum load capacity. It’s an intelligent choice for craft show regulars, providing professional display capabilities without the investment in permanent fixtures. For heavy retail use or garage tool storage, consider a more robust fixed unit, but for flexible, occasional use, it’s hard to beat.

4. APshouhu Foldable Grid Wall Panels, Gridwall Panels with Folding Baskets, Tool-Free Assembly and Folding, for Storage and Retail Merchandise Display (Black)

Overview: This compact foldable gridwall system from APshouhu prioritizes convenience and value, offering a complete storage solution in one package. The three-panel design folds flat for easy storage and includes three independent hooks, a grid front panel, and a folding basket. Measuring smaller than commercial units, it’s tailored for home offices, craft rooms, small retailers, and trade show vendors with limited space.

What Makes It Stand Out: The tool-free folding mechanism and included accessories distinguish this model. The galvanized steel construction with rust-proof coating ensures durability despite the budget price. The folding baskets add immediate functionality that competitors require separate purchases to achieve. Its compact size when folded makes it ideal for apartment dwellers or mobile vendors using personal vehicles.

Value for Money: At $75.99, this is the best value package for entry-level users. Including hooks and a basket eliminates initial accessory costs, while the foldable design saves on storage solutions. While not as heavy-duty as premium units, it offers sufficient strength for light retail merchandise, craft supplies, or home organization, making it accessible for budget-conscious buyers.

Strengths and Weaknesses: Strengths include exceptional affordability, included accessories, tool-free operation, compact storage, and galvanized rust-resistant construction. The folding design is genuinely convenient for intermittent use. Weaknesses include smaller display area, lower weight capacity than commercial units, and less stability than wheeled models. The three-panel design may feel limiting compared to larger four-panel systems, and the absence of wheels reduces mobility.

Bottom Line: This APshouhu gridwall is perfect for beginners, hobbyists, and small-space dwellers. It delivers immediate functionality at an unbeatable price point, though serious retailers will need larger, more robust systems. For home craft storage, light retail display, or occasional event use, it provides outstanding value and convenience that outweighs its capacity limitations.

5. Wall Photo Grid Shelf, Wall Hanging Ins Art Display Grid Panel for Decor & Storage, Metal Wire Notice Boards & Memo Board, Mesh Tool Organiser, Wall Photo Frame 2 Pcs (Black, 15.7 x 31.5 inches)

Overview: This decorative gridwall set shifts focus from commercial displays to aesthetic home organization. Sold as two 15.7 x 31.5-inch panels, these wall-mounted grids serve as photo displays, memo boards, and light storage solutions. The black-coated wire construction targets dorm rooms, bedrooms, and home offices where style matters as much as function. This is organization reimagined as wall art.

What Makes It Stand Out: The Instagram-ready aesthetic distinguishes these panels from utilitarian gridwall systems. Designed for hanging photos, lights, and small accessories, they transform clutter into curated displays. The included mounting hardware and 12-month warranty demonstrate consumer-focused support rare in this category. Their compact size suits renters and minimalists seeking non-permanent organization.

Value for Money: At $34.99 for two panels ($17.50 each), this is an accessible entry point for decorative organization. While unsuitable for heavy merchandise, the price reflects the design-forward approach and included warranty. Comparable decorative grids from home goods retailers often cost more with inferior mounting systems, making this a smart buy for aesthetic purposes.

Strengths and Weaknesses: Strengths include attractive design, easy installation, included mounting hardware, warranty protection, and versatility for photos, notes, and lightweight items. The compact size fits anywhere. Weaknesses include limited weight capacity, unsuitability for commercial merchandise, requirement for wall mounting (damaging walls), and small dimensions that restrict organizational capacity. The decorative focus sacrifices utilitarian strength.

Bottom Line: These grid panels excel as decorative organization for living spaces, not commercial displays. They’re perfect for students, renters, and anyone wanting to blend storage with style. For hanging keys, jewelry, photos, and plants, they deliver excellent value. However, retailers and garage organizers should look elsewhere. Purchase these for aesthetic enhancement, not heavy-duty storage.

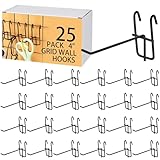

6. Moxweyeni 4 Inch Grid Wall Hooks 25 Pcs Gridwall Panel Hooks Store Garage Wall Mount Organizers Storage Grid Display Hangers for Retail, Craft Show, Home Setup, Customized Display (Black)

Overview: These 25-pack stainless steel gridwall hooks offer a simple, effective solution for organizing and displaying items across multiple environments. At 4 inches long with a 0.13-inch thickness, they’re designed to fit standard gridwall panels without tools or drilling. The electroplated black finish provides rust resistance for both indoor and outdoor applications, making them suitable for garages, retail spaces, craft shows, and home storage needs.

What Makes It Stand Out: The sheer quantity and universal compatibility make these hooks particularly compelling. Unlike panel-and-hook combo sets, this package lets you expand existing gridwall systems affordably. The stainless steel construction supports surprisingly heavy loads relative to their size, while the tool-free installation means you can reconfigure your display in seconds. Their versatility extends from hanging small craft items to heavier tools, offering flexibility that single-purpose organizers lack.

Value for Money: At $0.72 per hook, this 25-pack delivers excellent bulk value. Comparable individual hooks often retail for $1-2 each, making this set economical for large projects. The durability ensures you won’t need replacements, and the multi-room applicability maximizes your investment. For retailers or craft show vendors needing consistent displays, the uniform appearance and quantity justify the upfront cost.

Strengths and Weaknesses: Pros: Excellent bulk pricing; durable stainless steel construction; rust-proof finish; tool-free installation; versatile applications; consistent sizing. Cons: Hooks only—panels sold separately; 4-inch length may be too short for some items; black finish could scratch over time; no weight rating specified.

Bottom Line: These hooks are a smart purchase for anyone with existing gridwall panels needing reliable, affordable accessories. They excel in retail and craft environments where flexibility matters, though buyers should verify their grid spacing compatibility first.

7. Only Garment Racks #1900B (Box of 3) Grid Panel for Retail Display - Perfect Metal Grid for Any Retail Display, 2’x 6’, 3 Grids Per Carton (Black Finish)

Overview: This three-pack of heavy-duty steel grid panels targets retail and commercial users seeking durable display solutions. Each 2’x6’ panel features a black finish and robust construction designed to support substantial weight. The panels can be wall-mounted or configured as freestanding units with separate bases, offering flexibility for stores, trade shows, or home organization projects where professional presentation matters.

What Makes It Stand Out: The commercial-grade steel construction distinguishes these panels from lighter-duty alternatives. They’re engineered to handle heavy merchandise like sports equipment or housewares without bending. The modular design allows for both permanent wall installation and temporary freestanding setups, adapting to changing retail layouts. Selling in a three-pack provides immediate coverage for larger display areas.

Value for Money: At $91.95 for three panels ($30.65 each), these sit in the mid-to-premium range. While more expensive than basic panels, the heavy-duty construction justifies the cost for commercial applications where failure isn’t an option. For home users, the investment makes sense only if you need serious weight capacity. Budget-conscious buyers might find better value in lighter-duty options.

Strengths and Weaknesses: Pros: Heavy-duty steel construction; versatile mounting options; professional black finish; holds substantial weight; easy to rearrange; three panels provide good coverage. Cons: Higher price point; bases sold separately; heavier than standard panels; may be overkill for light home use; finish can chip if mishandled.

Bottom Line: Ideal for retailers and serious vendors needing reliable, professional displays. The sturdy construction justifies the premium price for commercial use, though casual home organizers can find more economical alternatives.

8. Koretech Grid Wall Panels 3 Pcs, Commercial Grade Gridwall Panels, Metal Grid Wall Panel Display Stand, You Can DIY 6 Pack 2’x3’ or 3 Pack 2’x6’ (Black)

Overview: Koretech’s three-pack system offers commercial-grade steel panels with thick PVC coating, providing durability with a more refined finish. The standout feature is configurability: use them as three 2’x6’ panels or six 2’x3’ sections, adapting to different spaces. At $69.99, they target users wanting professional quality without the premium price tag of full retail systems.

What Makes It Stand Out: The configurable design is the main selling point. This adaptability lets you create smaller displays for craft shows or combine panels for wall-mounted home organization. The PVC coating provides better scratch resistance than standard paint finishes. With a combined 6’x6’ coverage area, they offer substantial display real estate while maintaining portability for vendors who transport their setups.

Value for Money: These panels strike an excellent balance between quality and cost. At roughly $23 per panel, they’re cheaper than Product 7 while offering similar commercial-grade construction. The included configuration flexibility adds value, essentially giving you two systems in one. For craft show vendors and home users wanting professional results, this represents strong mid-range value.

Strengths and Weaknesses: Pros: Configurable sizing; durable PVC coating; commercial-grade steel; versatile mounting options; good size coverage; competitive pricing. Cons: Hardware for mounting/bases not included; PVC coating may wear at connection points; heavier than economy panels; assembly requires planning for optimal configuration.

Bottom Line: A versatile, well-priced solution for serious home organizers and mobile vendors. The configurable design and durable coating make it superior to basic panels, though you’ll need to purchase hanging hardware separately.

9. Urban Deco Grid Wall Panel Display Stand, 2.2’ x 6.2’ FT Gridwall Panel with Extra 8 Hooks, Craft Show Display Rack Black Metal Grids Standing Wire Rack for Retail Merchandise

Overview: Urban Deco’s all-in-one package includes a single 2.2’x6.2’ grid panel, eight hooks, and a wheeled stand, targeting craft show vendors and retailers needing mobility. The lockable wheels and freestanding design eliminate installation requirements, while the included hooks provide immediate functionality. At $44.99, it’s positioned as a convenient entry-level solution for mobile displays.

What Makes It Stand Out: Portability defines this product. The wheeled stand with locking brakes allows effortless repositioning during events, a feature absent in wall-mounted-only systems. Including eight hooks adds out-of-box value, saving separate purchases. The slightly larger dimensions (2.2’ vs standard 2’) provide extra display space without significantly increasing footprint. The stand design means no wall damage—perfect for temporary venues.

Value for Money: This package offers excellent convenience value. Comparable panels alone cost $25-35, and adding a quality stand and hooks would exceed $60 separately. For craft show vendors, the time saved on setup and breakdown justifies the price. However, the single-panel limitation makes it less economical for larger displays compared to multi-panel packs.

Strengths and Weaknesses: Pros: All-in-one mobile solution; lockable wheels for stability; includes 8 hooks; tool-free assembly; no wall mounting required; good for temporary setups. Cons: Only one panel; stand may wobble with heavy items; wheels add bulk for transport; limited expansion options; not suitable for permanent wall installation.

Bottom Line: Perfect for mobile vendors and craft show participants prioritizing portability. The wheeled design and included accessories make it a turnkey solution, though serious retailers will need multiple units for adequate display space.

10. VEVOR 3 Packs Grid Wall Panels, 2 x 6 ft Wire Grid Panels Display Rack, Wall-Mounted Art Display Shelf, Black Carbon Steel Wall Hanging Gridwall for Craft Show, Decoration, Storage, Notice Board

Overview: VEVOR’s three-pack delivers heavy-duty carbon steel panels with a powder-coated finish at a competitive $49.90 price point. Each 2’x6’ panel supports up to 20 lbs, targeting budget-conscious buyers wanting sturdy wall-mounted storage. The package includes wall-mount hardware, positioning itself as a complete solution for home, office, and retail environments where permanent installation is acceptable.

What Makes It Stand Out: The impressive weight capacity (20 lbs per panel) combined with the low price creates exceptional value. The powder-coated finish offers better durability than painted surfaces, while the included mounting hardware eliminates extra purchases. VEVOR’s reputation for industrial-grade products suggests these panels can handle demanding applications. The minimalist aesthetic works in modern homes and professional settings alike.

Value for Money: This is among the best values in the category. At under $17 per panel, you’re getting heavy-duty construction comparable to panels costing twice as much. The included hardware and 20-lb capacity make it suitable for real storage, not just light display. For wall-mounted applications, it’s hard to beat this price-to-performance ratio.

Strengths and Weaknesses: Pros: Excellent price; heavy-duty carbon steel; high weight capacity; powder-coated finish; includes mounting hardware; minimalist design; versatile applications. Cons: Wall-mount only (no freestanding option); hooks/clips sold separately; finish may scratch during installation; limited configuration flexibility; instructions could be clearer.

Bottom Line: An outstanding value for permanent wall-mounted installations. The sturdy construction and included hardware make it ideal for home and office organization, though mobile vendors should look elsewhere.

Understanding Grid Panel Systems for Tool Organization

Grid panel systems represent a quantum leap forward from traditional storage methods, offering a robust, adaptable framework for tool display that grows with your collection. Unlike conventional shelving or pegboard, these panels feature a uniform grid of square or rectangular openings that accept a vast array of hooks, brackets, bins, and specialty holders. The genius lies in their modularity—every component works together, yet nothing is permanent. You can reconfigure your entire layout in minutes without tools, adapting to new projects, seasonal tool rotations, or evolving work habits.

The Evolution from Pegboard to Modern Grid Systems

Remember the frustration of pegboard hooks falling out under load? Those 1/4-inch holes and flimsy fiberboard construction were never designed for serious tool weight. Modern grid panels emerged from industrial storage needs, where durability and adaptability weren’t negotiable. The transition from 1/4-inch holes to 3-inch grid spacing wasn’t arbitrary—it represents a fundamental rethinking of how tools are accessed and stored. Larger grid openings distribute weight more effectively, while heavy-gauge steel or aluminum construction provides the backbone needed for professional-grade loads. This evolution mirrors the shift from hobbyist tinkering to serious making, where tool organization directly impacts project timelines and safety.

Core Benefits of Implementing Grid Panels

The advantages extend far beyond mere tidiness. First, visual accessibility means you can identify and grab the right tool in seconds, reducing workflow interruption. Second, the vertical storage approach reclaims valuable bench and floor space—critical in cramped workshops where square footage comes at a premium. Third, the customizable nature supports lean manufacturing principles and 5S workplace organization: Sort, Set in Order, Shine, Standardize, Sustain. Your tool layout becomes a living system that reflects your actual usage patterns. Finally, proper tool display reduces damage; tools aren’t piled in drawers where edges dull and surfaces scratch. They hang safely, maintaining calibration and extending lifespan.

Material Selection Guide

Choosing the right material for your grid panels isn’t about picking the most expensive option—it’s about matching material properties to your specific environment, tool weight, and usage intensity. Each material brings distinct advantages and trade-offs that impact performance, longevity, and cost-effectiveness.

Steel Grid Panels: Industrial Strength Solutions

Steel remains the gold standard for heavy-duty applications, offering unparalleled tensile strength and rigidity. Look for panels constructed from 14-gauge to 18-gauge cold-rolled steel for optimal performance. The thickness matters enormously—14-gauge handles pneumatic tools and heavy power equipment, while 18-gauge suffices for hand tools and lighter gear. Steel’s primary advantage is its resistance to sagging under sustained load; a properly mounted steel panel can support hundreds of pounds without deformation. However, raw steel rusts aggressively in humid environments, making finish quality non-negotiable. Powder-coated steel with proper pretreatment withstands garage moisture and workshop chemicals, but once the coating chips, corrosion begins its inevitable march.

Aluminum Grid Panels: Lightweight Versatility

Aluminum panels shine in mobile applications or where wall structure can’t support steel’s heft. Weighing roughly one-third of comparable steel panels, aluminum reduces mounting stress on drywall and makes reconfiguration feasible for one person. The material naturally forms a protective oxide layer, offering inherent corrosion resistance without relying on coatings. For marine environments, food service, or chemical-exposed workshops, anodized aluminum provides superior protection while maintaining a professional appearance. The trade-off? Lower weight capacity—typically 30-40% less than steel—and higher cost per square foot. Aluminum also scratches more easily, potentially marring aesthetic appeal in customer-facing spaces.

Plastic Composite Panels: Corrosion-Resistant Alternatives

High-density polyethylene (HDPE) or reinforced polymer panels excel in environments where metal fails: outdoor installations, wash-down areas, and chemical-heavy workspaces. These panels won’t rust, corrode, or conduct electricity, making them ideal for electronics work or around saltwater. Modern composites achieve surprising strength through ribbed designs and reinforced backing, though they still can’t match metal for absolute load capacity. UV-stabilized formulations prevent sun degradation, crucial for garage doors that receive direct sunlight. The downside? Limited accessory compatibility—most metal hooks won’t seat properly, requiring proprietary plastic accessories that may cost more and offer fewer style options.

Grid Patterns and Spacing Standards

The grid pattern defines your system’s flexibility and accessory compatibility. While variations exist, industry standards have emerged that ensure cross-compatibility between panels and accessories from different manufacturers.

Standard 3-Inch Grid Spacing Explained

The ubiquitous 3-inch grid spacing (measured center-to-center) dominates the market for good reason. This dimension balances tool density with accessibility—too close and hooks interfere; too far apart and you waste vertical space. The 3-inch spacing creates a modular system where accessories align perfectly, allowing you to span multiple grid openings for larger tools or create stable shelving platforms. When evaluating panels, verify the opening size, not just spacing. True 3-inch grids typically feature 1-inch square openings, providing ample engagement for hook shoulders while maintaining structural integrity. Some budget panels use 3-inch spacing with smaller openings, limiting accessory options.

Metric vs. Imperial Grid Systems

International manufacturers sometimes produce 75mm grid spacing (roughly 2.95 inches), which appears compatible but creates subtle alignment issues over larger installations. While a single hook might fit, accessories spanning multiple grids—like shelf brackets or paper holders—won’t align properly. For workshops mixing panels from different sources, stick to pure imperial measurements. If you’re starting fresh and sourcing internationally, commit entirely to metric to ensure perfect compatibility. The difference seems minor until you’re trying to mount a 24-inch shelf across four panels and discover the mounting holes are 3/16-inch off.

Mounting Configurations

How you mount your grid panels dramatically affects their effective weight capacity, accessibility, and impact on your workspace. Each configuration serves different workflow needs and structural realities.

Wall-Mounted Systems: Maximizing Vertical Space

Wall mounting remains the most common approach, but installation method separates professional results from DIY disasters. Direct-to-stud mounting using 2-1/2-inch lag bolts provides maximum strength, essential for steel panels loaded with heavy tools. For installations spanning multiple panels, horizontal furring strips create a consistent mounting plane and allow minor adjustment. Never mount heavy panels directly to drywall using toggle bolts alone—the weight will eventually pull through. For concrete or block walls, use 1/4-inch concrete anchors minimum, spaced every 12 inches around the perimeter. Consider leaving a 1/2-inch gap between panel and wall using spacers; this gap allows hooks to fully seat and prevents wall damage from tool contact.

Freestanding Grid Panel Configurations

When wall space is unavailable or you need flexibility, freestanding systems built from multiple panels connected by corner brackets create self-supporting partitions. These configurations work brilliantly for dividing workshop zones or creating tool islands accessible from both sides. The key lies in triangulation—connect at least three panels in an L-shape or U-shape for stability. Base plates should extend at least 12 inches from the panel face to prevent tipping, and diagonal bracing becomes mandatory for panels over 48 inches tall. Freestanding systems sacrifice some rigidity compared to wall mounting, so reduce weight capacity expectations by 25-30%.

Mobile Grid Panel Carts and Stations

For mobile technicians or shared workshop tools, wheeled grid panel carts combine storage with portability. Look for 5-inch diameter locking casters minimum—smaller wheels snag on floor debris and make movement jerky. The frame should be welded steel tube, not bolted, as bolted joints loosen under vibration. Weight distribution becomes critical; mount heaviest tools at the bottom to lower the center of gravity and prevent tipping. Electrical integration adds tremendous value—carts with built-in power strips and cord reels keep charging tools organized and ready. Mobile units typically support 150-200 pounds total, far less than wall-mounted equivalents, but the trade-off in flexibility justifies the capacity reduction for many users.

Weight Capacity and Load Management

Understanding weight ratings prevents catastrophic failures and ensures your system remains safe after years of use. Manufacturer ratings often reflect ideal conditions that rarely exist in real workshops.

Dynamic vs. Static Load Considerations

Static load—the weight of tools hanging motionless—represents only part of the equation. Dynamic loads occur when you remove and replace tools, creating momentary shock loads that can exceed static weight by 50-100%. Pneumatic tools, especially, create dynamic loads as you yank hoses. Panels rated for 100 pounds static might fail with 75 pounds of tools if you’re constantly grabbing and replacing items. For high-activity zones, derate manufacturer specifications by 30% to build in a safety margin. Also consider concentrated loads: a 20-pound angle grinder creates more stress hanging from a single hook than four 5-pound tools distributed across four hooks.

Safety Factors and Real-World Performance

Reputable manufacturers design panels with a safety factor of 3:1 or 4:1, meaning the panel won’t deform until loads exceed three to four times the rated capacity. However, this assumes perfect installation and even weight distribution. In practice, safety factors erode through installation imperfections, material fatigue, and environmental degradation. A panel rated for 200 pounds might sag noticeably at 150 pounds after two years of temperature cycling in an uninsulated garage. For critical applications or overhead installations, specify panels with higher gauge steel (lower numbers) than you think you need. The modest increase in cost pays dividends in peace of mind and system longevity.

Accessory Compatibility

Your grid panel is only as useful as the accessories that integrate with it. A thriving ecosystem of hooks, bins, and specialty holders transforms a simple panel into a comprehensive organization solution.

Hook Design Variations for Different Tool Types

Standard L-hooks work for many tools, but specialty hook designs solve specific problems. Double-prong hooks distribute weight across two grid openings, perfect for heavy drills or sanders. J-hooks with retaining clips prevent tools from bouncing out when doors slam or when mobile carts traverse uneven floors. For torque wrenches and precision instruments, padded hooks protect calibration-critical surfaces. Consider angled hooks for pliers and scissors—the slight downward angle keeps jaws closed and prevents tools from sliding off. When evaluating hooks, examine the shoulder thickness where it engages the panel; thicker shoulders (3/16-inch minimum) resist bending and maintain secure engagement under load.

Integrated Shelving and Bin Systems

True workspace optimization requires more than hooks. Shelf brackets that lock into multiple grid openings create platforms for power tool cases, spray paint cans, or material stock. Look for brackets with integrated retaining lips that prevent items from sliding off during vibration. Plastic bins with dedicated grid hangers organize fasteners, drill bits, and small parts, keeping them visible yet contained. The best systems feature bins with label holders and clear fronts for inventory management. For aerosol cans and cylindrical items, spring-loaded clips grip securely while allowing one-handed retrieval. When planning shelving, remember that deep shelves (12+ inches) obscure tools hung behind them—balance storage depth with tool accessibility.

Workspace Layout Strategies

Randomly hanging tools creates visual chaos and inefficiency. Strategic layout planning based on workflow patterns and ergonomic principles maximizes the return on your grid panel investment.

The Ergonomic Zone Principle

Divide your workspace into three vertical zones based on reach frequency. The primary zone (waist to shoulder height) hosts tools used daily—hammers, screwdrivers, your go-to drill. Secondary zone (knee to waist and shoulder to reach limit) stores weekly-use items like specialty saws or less-common wrench sets. The tertiary zone (above reach limit or below knees) houses seasonal or backup tools. This zoning reduces repetitive strain and minimizes time spent searching. For shared workspaces, implement shadow boards—outlining each tool’s position on the panel so missing items become immediately obvious. This visual cue maintains organization without constant policing.

Visual Management and Color Coding Strategies

Color transforms grid panels from storage into management systems. Use colored bin clips to designate fastener types (red for metric, blue for SAE). Paint hook tips different colors to indicate tool ownership in shared shops. Some manufacturers offer panels in multiple colors—black for metalworking tools, white for electronics, creating departmental boundaries at a glance. For mobile technicians, color-coded panels on carts identify specialty (red for electrical, green for plumbing). This visual language reduces errors and speeds tool retrieval, especially for apprentices or in high-pressure situations where grabbing the wrong tool wastes precious minutes.

Durability and Finish Options

The finish on your grid panels does more than look pretty—it determines how the system withstands chemical exposure, abrasion, and environmental conditions over years of service.

Finish Types: Powder Coating, Galvanization, and Anodization

Powder coating dominates steel panels, offering excellent abrasion resistance and color options. The key lies in pretreatment: panels that are phosphate washed before coating resist chipping far better than those simply wiped clean. For extreme environments, galvanized steel (hot-dip or electrogalvanized) provides sacrificial protection—zinc corrodes before steel, even where scratched. Anodized aluminum creates a hard, integrated surface layer that won’t chip or peel, ideal for coastal workshops where salt air attacks everything. Clear anodizing maintains aluminum’s natural appearance while providing protection. Avoid painted finishes on aluminum; they scratch easily and offer minimal corrosion benefit over bare metal.

Environmental Resistance Factors

Workshop environments vary wildly, and your finish must match your reality. In uninsulated garages subject to temperature swings and condensation, galvanized or properly powder-coated steel outperforms bare metal. For wash-down areas or chemical exposure (think automotive shops with brake cleaner and oil), anodized aluminum or specialized chemical-resistant powder coatings prevent degradation. UV exposure from windows or open bay doors fades standard powder coats over time; specify UV-stable formulations for sun-exposed installations. In food service or medical environments, stainless steel panels (though expensive) provide the ultimate in corrosion resistance and cleanability, meeting strict sanitation standards.

Investment and ROI Analysis

Grid panel systems range from budget-friendly to premium industrial grades. Understanding the true cost involves looking beyond initial purchase price to installation, accessories, and long-term value.

Initial Investment vs. Long-Term Value

Entry-level steel panels cost $15-25 per square foot, while premium industrial systems reach $40-60. The difference isn’t just marketing—thicker steel, superior finishes, and precision manufacturing ensure the premium panel still looks professional after a decade while the budget option sags and rusts. Factor in accessory costs: a comprehensive hook and bin assortment often exceeds panel cost. Budget $3-5 per tool for quality accessories. Installation costs vary widely; DIY mounting on exposed studs costs nothing but time, while professional installation on finished drywall with backing reinforcement runs $200-400 per panel. However, professional installation ensures optimal weight distribution and prevents costly wall repairs later.

Scalability and Expansion Costs

One of grid panels’ greatest strengths is expandability, but mixing panel types creates compatibility headaches. Standardizing on one system from the start allows seamless expansion. When budgeting, purchase 20-30% more panel capacity than currently needed—tool collections grow, and matching panels years later proves difficult as manufacturers update product lines. Some systems offer connector kits to join panels into larger arrays, reducing per-panel cost for big installations. Consider buying panels in bulk packs (typically 4-6 panels) for 15-20% savings over individual purchase. The real ROI emerges through time savings: technicians report 15-30 minutes daily savings searching for tools. Over a year, that’s 60-120 hours of recovered productivity—far exceeding the system’s cost.

Maintenance Requirements

Even the most durable grid panels require periodic maintenance to maintain appearance and function. Neglect leads to rust, accessory binding, and eventual system failure.

Cleaning Protocols for Different Materials

Steel panels with powder coating clean easily with mild detergent and water—avoid abrasive cleaners that dull the finish. For oily buildup, mineral spirits on a rag (not sprayed) cuts through grime without damaging coating. Aluminum panels tolerate more aggressive cleaning but scratch easily; use soft brushes and avoid steel wool. Plastic composite panels handle pressure washing, making them ideal for dirty environments, but check that pressure doesn’t exceed panel rating (typically 1500 PSI). Quarterly cleaning prevents buildup that interferes with hook engagement. In salt-exposed environments, monthly rinsing with fresh water prevents corrosion initiation, especially around mounting hardware where coatings are thin.

Preventative Maintenance Schedules

Every six months, inspect all mounting hardware for loosening—vibration from power tools gradually backs out screws. Re-tighten to specified torque (typically 20-25 ft-lbs for lag bolts). Check panel faces for hook abrasion; heavily used areas may need touch-up paint to prevent rust. Lubricate hook shoulders annually with dry silicone spray to prevent binding and reduce wear. For mobile units, inspect caster bearings and tighten axle nuts quarterly. Replace any bent hooks immediately—bent hooks don’t seat properly and create point loads that damage panel grids. Document your maintenance schedule; a simple checklist taped inside a cabinet door ensures consistency.

Industry-Specific Considerations

Different trades impose unique demands on grid panel systems. Understanding these specialized requirements prevents purchasing mistakes and ensures your system integrates seamlessly with industry-specific workflows.

Automotive and Mechanic Shops

Auto shops demand maximum weight capacity and chemical resistance. Pneumatic tools, impact wrenches, and torque wrenches create concentrated loads exceeding 15 pounds each. Specify 14-gauge steel panels with galvanized or premium powder-coat finishes. Position panels away from direct blast from parts washers, but within arm’s reach of service bays. Integrate hose reels and electrical outlets directly into panel systems to keep power and air connections organized. Consider double-depth panels (two panels spaced 6 inches apart) for storing long pry bars and extensions vertically without interfering with wall contact.

Woodworking and Craft Studios

Woodworking generates fine dust that infiltrates every surface, making smooth finishes critical. Powder-coated steel with electrostatic-dissipative properties prevents dust buildup through static attraction. Position panels to avoid direct spray from dust collection ports but within the primary work triangle (table saw, workbench, assembly area). For hand tool storage, smaller grid spacing (2-inch) sometimes works better, allowing dense arrangement of chisels, marking gauges, and layout tools. Many woodworkers prefer black or dark gray panels that make steel tools visually pop, reducing grab time. Integrate magnetic strips for holding chisels and plane irons—some grid panels accept magnetic accessories that augment hook-based storage.

Commercial Kitchens and Food Service

Health codes dictate strict sanitation requirements, favoring stainless steel or NSF-certified plastic panels. Mount panels on casters for easy movement during deep cleaning. Avoid steel in areas exposed to steam and constant moisture—galvanized coatings eventually fail under relentless humidity. Instead, anodized aluminum or specialized food-grade plastic panels withstand daily wash-downs. Store utensils and smallware in removable, dishwasher-safe bins that hang from grid panels. Color-coding becomes mandatory for allergen control—dedicated panels for nut-free, gluten-free, or dairy-free tools prevent cross-contamination. Ensure all accessories have smooth, crevice-free designs that won’t harbor bacteria.

Customization and Branding Options

Grid panels don’t have to be utilitarian gray. Modern manufacturing offers customization that integrates storage systems into your brand identity or workshop aesthetic.

Color Customization and Aesthetic Integration

Beyond standard black, white, and gray, many manufacturers offer custom powder-coating in any RAL color for a modest upcharge (typically 15-25%). This allows matching corporate colors in commercial settings or coordinating with workshop décor in home garages. Two-tone designs—different colors for different departments or tool categories—create visual organization at the panel level. Some shops paint panel edges in bright colors to create “frames” that draw attention to specific zones. For customer-facing areas, consider panels with lower grid density and integrated backlighting, creating a showroom appearance while maintaining functionality.

Branding and Logo Integration

Laser-etched or vinyl-cut logos applied directly to panels reinforce brand identity in maker spaces or corporate workshops. Some manufacturers embed logos into the panel grid itself during manufacturing, creating a permanent, professional appearance. For mobile service operations, magnetic vinyl banners attach to steel panels, turning storage into rolling billboards. When specifying branded panels, ensure logos don’t interfere with grid openings or create stress concentration points. Position branding in upper corners or center sections where accessory density tends to be lower.

Installation Best Practices

Proper installation determines whether your grid panel system becomes a generational asset or a wall-damaging liability. Cutting corners during installation guarantees future problems.

Tools and Preparation Requirements

Before purchasing panels, assess your wall structure. Drywall over studs requires locating every stud and planning panel placement accordingly. Use a high-quality stud finder that detects both edges of each stud, marking centerlines with painter’s tape. For concrete or brick, rent a hammer drill with 3/16-inch masonry bits. You’ll need a level (4-foot minimum), drill with torque clutch, socket set for lag bolts, and potentially a laser level for multi-panel alignment. Create a full-scale layout on the wall using cardboard templates or painter’s tape to visualize spacing before drilling. This prevents the “measure twice, drill once” frustration.

Professional vs. DIY Installation

DIY installation saves money but demands precision. If you’re hanging a single 24x48-inch panel in a garage with exposed studs, DIY is straightforward. However, large installations spanning multiple panels on finished drywall justify professional help. Pros bring experience with backing board installation—mounting 3/4-inch plywood across studs creates a continuous mounting surface that distributes loads and allows panel placement anywhere, not just on stud lines. They also understand load paths and can reinforce areas behind drywall before installation. Professional installation typically includes warranty coverage for both panels and wall integrity, valuable insurance for expensive installations.

Common Mistakes to Avoid

Even seasoned workshop managers fall prey to predictable errors when implementing grid panel systems. Learning from others’ mistakes saves time, money, and wall repairs.

Overloading and Weight Distribution Errors

The most common mistake is treating the panel’s total weight rating as a per-hook guideline. A panel rated for 200 pounds doesn’t mean you can hang four 50-pound items on four hooks. Concentrated loads near panel centers create maximum bending stress. Distribute heavy items across multiple hooks and position them near mounting points (typically panel edges). Another error is ignoring tool growth—buying exactly enough panel space for current tools guarantees a cluttered expansion later. Plan for 30% growth minimum. Finally, avoid mounting panels too high. The top row should remain reachable without a step stool; otherwise, tools migrate to the accessible lower rows, creating imbalance.

Poor Planning and Measurement Issues

Failing to account for door swings, window openings, and electrical panels creates inaccessible or blocked storage. Measure twice, considering full tool projection from the panel—large tools like circular saws extend 8-12 inches from the wall. Another planning failure is ignoring lighting. Panels mounted in shadowed areas make tool identification difficult, negating visual organization benefits. Install supplemental lighting before panel mounting. Perhaps most critically, don’t assume all accessories fit all panels. Test-fit a few critical accessories before committing to a large purchase, verifying hook engagement depth and stability.

Frequently Asked Questions

How much weight can a typical grid panel actually hold?

Standard 18-gauge steel panels with wall-mounted installation typically support 150-200 pounds distributed across the panel surface. However, real-world capacity depends on mounting quality, weight distribution, and whether loads are static or dynamic. For heavy tool collections, specify 14-gauge panels rated for 300+ pounds, and always derate manufacturer specs by 20-30% for safety margin.

What’s the difference between grid panels and slatwall for tool storage?

Grid panels feature square openings in a uniform pattern, accepting accessories from both horizontal and vertical directions, while slatwall uses horizontal slots that limit accessory orientation. Grid panels generally support heavier loads and offer more flexible accessory positioning. Slatwall excels in retail environments for displaying packaged goods but lacks the robustness serious tool storage demands.

Can I mount grid panels on drywall without finding studs?

Never mount heavy-loaded panels directly to drywall. While toggle bolts might support light loads temporarily, they will eventually pull through. Always mount to studs or install 3/4-inch plywood backing anchored to studs every 16 inches. For concrete or brick walls, use appropriate masonry anchors rated for the panel’s weight.

How do I prevent hooks from falling out when I grab tools?

Quality hooks feature retaining clips, spring-loaded detents, or angled shoulders that lock into grid openings. Avoid cheap L-hooks that rely solely on gravity. For high-vibration environments, wrap a small zip tie around the hook shaft behind the panel face—snip it flush and the hook becomes permanently captured while remaining removable with scissors.

What’s the best grid panel material for humid garage environments?

Anodized aluminum offers the best corrosion resistance without maintenance, though at premium cost. Galvanized steel provides excellent protection at moderate price points. If choosing powder-coated steel, ensure it’s phosphate-pretreated and specify a marine-grade or chemical-resistant powder formulation. Avoid bare steel or standard paint finishes in humid conditions.

How far apart should I space multiple grid panels?

Mount panels with zero gap between them for seamless accessory spanning. If you must separate panels (to work around obstacles), keep gaps under 1/4-inch to prevent small items from falling through. For aesthetic spacing, use narrow trim pieces between panels, but recognize this prevents accessories from bridging the gap.

Can grid panels support cabinets or heavy shelving?

Yes, with proper reinforcement. Use heavy-duty shelf brackets that engage at least four grid openings and distribute load across multiple mounting points. For cabinets, mount a 2x4 horizontal rail to studs first, then attach the cabinet and panel to the rail. Never hang cabinets solely from the grid panel—panels support contents, not the cabinet structure itself.

How do I clean oily buildup from grid panels without damaging the finish?

Use a degreasing cleaner like Simple Green or diluted Dawn dish soap with a soft brush. Apply with minimal water to prevent moisture behind panels. For stubborn buildup, mineral spirits on a rag (never sprayed) cuts through grease. Avoid pressure washers on powder-coated steel—the force can chip coating edges. Rinse with damp cloth and dry thoroughly.

Are grid panel accessories universal across brands?

Most accessories designed for 3-inch grid spacing are cross-compatible, but quality varies enormously. Hook shoulder thickness, engagement depth, and material strength differ between manufacturers. Premium accessories often fit tighter and support more weight. Before buying accessories in bulk, test a few samples with your specific panels to verify secure fit and stability under load.

How do I plan a grid panel layout for maximum efficiency?

Start by auditing your tools—group by frequency of use, then by size and weight. Sketch your wall space to scale on graph paper, marking permanent obstacles. Place daily-use tools in the primary ergonomic zone (waist to shoulder height). Use full-scale cardboard templates to test layout before installation. Plan for 30% growth and leave accessible space for future additions. Finally, walk through your typical workflow, ensuring tool placement supports natural motion patterns rather than forcing awkward reaches.