Remember when “some assembly required” meant spending three hours deciphering hieroglyphic instruction manuals, only to discover you were missing three crucial screws? Those days are officially behind us. As we move into 2026, the furniture industry has undergone a quiet revolution—one where engineering precision meets intuitive design to create workspaces that literally snap together in minutes, no tools, no frustration, no leftover hardware mysteriously multiplying in your junk drawer.

This isn’t just about convenience; it’s about reimagining how we interact with our environments. Tool-free modular desks represent a fundamental shift toward adaptive living, where your workspace evolves as quickly as your needs do. Whether you’re a remote professional carving out a corner in a studio apartment, a gamer building the ultimate streaming command center, or a facility manager outfitting an entire hybrid office floor, understanding what makes these systems truly exceptional will save you time, money, and a significant amount of sanity. Let’s dive deep into the engineering, materials, and design principles that separate the merely functional from the genuinely transformative.

Top 10 Modular Desks That Snap Together

Detailed Product Reviews

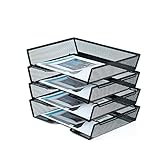

1. SETTFRFE 4 Tier Metal Mesh Desk Organizer-Stackable Letter Trays for Office Supplies,Black File Storage System with Reinforced Edges

Overview: The SETTFRFE 4 Tier Metal Mesh Desk Organizer delivers a robust solution for taming desk clutter. This black steel mesh system offers four stackable trays measuring 12.2"x9.8" each, providing ample space for letter-sized documents and office supplies. With tool-free assembly and a modular design, it promises instant organization without the hassle of complicated setup.

What Makes It Stand Out: The reinforced edge design distinguishes this organizer from flimsy competitors, ensuring durability under daily use. Its intelligent stackable configuration lets you create a vertical tower or distribute trays across your workspace. The open-grid mesh construction serves a dual purpose: preventing paper curl through airflow while offering instant visibility of contents. This versatility transforms it from a simple file holder into a comprehensive desk management system.

Value for Money: At $27.95, this organizer sits in the mid-range price bracket, offering commercial-grade construction at a consumer-friendly price point. Comparable metal mesh systems often cost $35-45, while plastic alternatives lack the durability and premium feel. The modular capability essentially provides four separate organizers in one, multiplying its value proposition.

Strengths and Weaknesses: Strengths:

- Heavy-duty steel mesh with reinforced edges prevents warping

- Tool-free snap assembly takes under two minutes

- Modular design offers flexible configuration options

- Open-grid design promotes airflow and visibility

Weaknesses:

- Mesh openings may allow smaller items to slip through

- Black coating could chip over time with heavy use

- Stackable design might feel wobbly if not perfectly aligned

Bottom Line: This organizer hits the sweet spot between durability, functionality, and price. Perfect for home offices or corporate settings, it transforms chaotic desks into streamlined workstations. The tool-free assembly and modular versatility make it a worthwhile investment for anyone serious about organization.

2. Xyntor 96 Hole Pen Holder Organizer | Modular DIY Desk Storage for Pens/Pencils/Brushes | Space Saving Student & Office Supply Organizer | Strong Plastic Frame, Easy Assembly

Overview: The Xyntor 96 Hole Pen Holder Organizer revolutionizes writing utensil storage with its massive capacity and clever modular design. This compact 5.7-inch cube accommodates 96 pens, pencils, markers, or brushes in individually dedicated slots, making it ideal for students, artists, and professionals. Constructed from sturdy ABS plastic, it arrives in six pre-assembled components that snap together without tools.

What Makes It Stand Out: The sheer 96-slot capacity in such a tiny footprint sets this organizer apart. Unlike traditional cups or trays that create jumbled messes, each writing tool gets its own dedicated slot for instant identification and retrieval. The modular DIY approach allows customization of the configuration, while the portable design enables easy transport between classrooms, studios, or offices. Its transparent logic turns supply chaos into geometric order.

Value for Money: Priced at just $11.59, this organizer delivers exceptional value. Individual pen cups costing $5-8 each would require a dozen to match this capacity, while comparable high-capacity organizers typically run $20-30. The durable ABS construction ensures years of service, making this a budget-friendly powerhouse for organization enthusiasts.

Strengths and Weaknesses: Strengths:

- Unmatched 96-slot capacity in minimal desk space

- Sturdy ABS plastic prevents tipping and deformation

- Tool-free modular assembly and portability

- Instant visibility and access to all supplies

Weaknesses:

- Limited to standard-sized writing utensils

- All-plastic construction may not suit premium office aesthetics

- Full capacity required for optimal stability

- No option for larger supply storage

Bottom Line: For under $12, the Xyntor 96 Hole Organizer is a no-brainer for anyone with extensive writing tool collections. Its space-saving design and rock-solid construction make it perfect for students, artists, and office workers who value both capacity and organization. This is functional minimalism at its finest.

3. 3D Printed Modular Desk Cable Holder Cable Organizer with Clamp, Blue and Gray Interlocking Construction Pieces

Overview: This 3D Printed Modular Desk Cable Holder offers a customizable solution for managing cord clutter. Featuring interlocking blue and gray pieces with an integrated clamp mechanism, this organizer attaches securely to desk edges to keep charging cables, power cords, and wires neatly arranged. The snap-together design allows for quick configuration changes as your cable management needs evolve.

What Makes It Stand Out: The 3D printed construction enables a level of customization rarely seen in mass-produced cable organizers. Users can expand the system by adding more pieces, creating bespoke pathways for complex setups. The clamp mechanism provides sturdy edge attachment without adhesive damage, while the interlocking design lets you build vertical or horizontal runs. This adaptability makes it superior to rigid, one-size-fits-all solutions.

Value for Money: At $17.90, this organizer competes with premium cable management systems while offering unique modular benefits. Traditional adhesive clips cost $8-12 but lack reusability and expansion capability. The 3D printed construction ensures durability while supporting customization that would cost $25-40 in comparable modular systems.

Strengths and Weaknesses: Strengths:

- Fully customizable modular interlocking design

- Secure clamp attachment prevents desk damage

- Easy snap-together assembly and reconfiguration

- Durable 3D printed materials protect cables

Weaknesses:

- Limited to desk edges with compatible thickness

- Blue/gray color scheme may not match all setups

- 3D printed layers visible (aesthetic preference)

- Clamp strength may vary with desk material

Bottom Line: For tech-savvy users seeking adaptable cable management, this 3D printed solution excels. The modular design grows with your setup, while the clamp attachment preserves desk integrity. It’s an innovative, fairly-priced alternative to disposable adhesive clips, perfect for standing desks and evolving workspaces.

4. Mobile Folding Table, Folding Conference Table, Flip Top Rolling Mobile Table with Silent Locking Wheels, Rectangular Modular Conference Room Table for Office Meeting Room

Overview: This Mobile Folding Conference Table redefines flexible workspace furniture with its innovative flip-top design and silent rolling wheels. Measuring as a full-sized rectangular conference table, it features a rotary switch mechanism that collapses the surface vertically for compact storage. The E1-grade thickened board construction provides a scratch-resistant, easy-to-clean workspace suitable for meetings, dining, or collaborative projects.

What Makes It Stand Out: The integrated storage rack and privacy baffle elevate this beyond typical folding tables, offering personal item storage while concealing legs for a more professional aesthetic. The parent-child locking system enables seamless connection of multiple units, creating expansive conference configurations. Silent locking wheels provide mobility without the disruptive noise common in mobile furniture, making it ideal for dynamic office environments.

Value for Money: At $336.42, this table sits competitively in the mobile conference furniture market. Comparable folding conference tables range $300-500, but rarely include the storage rack, privacy panels, and modular connection features. The multi-scene versatility—as a desk, dining table, or meeting surface—effectively replaces several pieces of furniture, justifying the investment.

Strengths and Weaknesses: Strengths:

- Space-saving vertical folding with rotary switch

- Silent locking wheels for smooth repositioning

- Modular parent-child lock connects multiple tables

- Integrated storage and privacy baffle enhance functionality

- E1-grade board resists scratches and cleans easily

Weaknesses:

- Premium price point may exceed small business budgets

- Assembly required despite folding design

- Stability may not match fixed conference tables

- Wheels require periodic maintenance

Bottom Line: This mobile folding table excels in flexible workspaces where adaptability is paramount. The thoughtful additions—storage, privacy panels, and silent wheels—make it worth the premium for offices needing multi-purpose furniture. Perfect for conference rooms, coworking spaces, or studios where space optimization drives productivity.

5. Mobile Folding Table, Folding Conference Table, Flip Top Rolling Mobile Table with Silent Locking Wheels, Rectangular Modular Conference Room Table for Office Meeting Room

Overview: This Mobile Folding Conference Table delivers professional-grade flexibility with its flip-top design and silent mobility. The rectangular surface features a rotary switch for vertical folding, transforming from a full conference table to a slim storage profile in seconds. E1-grade thickened board construction ensures durability while four silent locking wheels enable effortless repositioning across office spaces.

What Makes It Stand Out: Beyond standard folding tables, this model incorporates a storage rack for personal items and a privacy baffle that conceals legs and enhances meeting aesthetics. The innovative parent-child locking system allows multiple tables to connect securely, creating custom conference configurations. The silent wheel operation distinguishes it from noisy mobile furniture, maintaining professional ambiance during setup changes.

Value for Money: Priced at $438.44, this listing commands a significant premium over identical alternatives. The same features—storage rack, privacy panels, E1-grade board, and silent wheels—are available from other sellers at $100 less. While the table itself offers excellent multi-scene functionality, savvy buyers should compare listings to avoid overpaying for identical specifications.

Strengths and Weaknesses: Strengths:

- Professional folding mechanism saves substantial space

- Whisper-quiet locking wheels protect meeting environments

- Modular design connects multiple units seamlessly

- Integrated storage and privacy features add value

- Durable E1-grade surface withstands heavy use

Weaknesses:

- Significantly overpriced compared to identical models

- Assembly complexity may challenge some users

- Mobile design sacrifices some fixed-table stability

- Premium cost limits accessibility for budget-conscious buyers

Bottom Line: The table itself is an exceptional piece of flexible furniture, but this specific listing’s price demands careful consideration. Identify your needs first, then shop around—identical features are available at more competitive prices. If budget isn’t constrained, it’s a stellar solution for dynamic workspaces; otherwise, seek alternative sellers for better value.

6. Mobile Folding Table, Folding Conference Table, Flip Top Rolling Mobile Table with Silent Locking Wheels, Rectangular Modular Conference Room Table for Office Meeting Room

Overview: This mobile folding conference table delivers exceptional versatility for modern, space-conscious workplaces. The unit transforms from a horizontal meeting surface to vertical storage via a rotary switch, featuring integrated storage racks and privacy baffles that conceal legs and protect personal belongings. Constructed with E1-grade thickened board and metal legs, it combines commercial durability with thoughtful design elements for dynamic office environments.

What Makes It Stand Out: The parent-child locking system enables seamless connection of multiple tables into custom configurations, a feature rarely found in folding furniture. Silent universal wheels provide true 360° mobility without disrupting meetings, while the privacy baffles address a common oversight in conference table design. The scratch-resistant surface and modular capability make it suitable for both permanent installations and temporary setups.

Value for Money: Priced at $582.43, this table sits in the premium tier but justifies its cost through multifunctionality. Comparable modular conference systems often exceed $800, and this eliminates separate purchases for storage units and privacy screens. For facilities managers and co-working spaces requiring frequent reconfiguration, the durability and time savings offset the initial investment over static alternatives costing $300-400 that lack mobility and connectivity features.

Strengths and Weaknesses: Strengths include superior mobility with silent wheels, space-saving vertical storage, modular connectivity, integrated privacy and storage features, and commercial-grade materials. Weaknesses involve the substantial price point, significant folded footprint requiring dedicated storage space, and aesthetic limitations—the baffles may clash with minimalist office designs. Assembly is moderately complex due to the locking mechanisms and wheel systems.

Bottom Line: This table excels for corporate training centers, co-working spaces, and multi-purpose meeting rooms prioritizing flexibility. While the price demands budget consideration, its unique combination of privacy features, mobility, and modular connectivity makes it a strategic investment for organizations needing adaptive workspace solutions that static furniture cannot provide.

The Rise of Tool-Free Assembly in Modern Workspace Design

The evolution from Allen wrenches to intuitive snap-fit connections didn’t happen overnight. It’s the culmination of advanced manufacturing tolerances, computer-aided stress analysis, and a consumer base that simply refused to accept assembly as a necessary evil. Furniture designers in 2026 are approaching desks more like LEGO sets than static structures, employing interlocking geometries that distribute load across multiple contact points rather than relying on a handful of threaded fasteners.

Why 2026 Is a Breakthrough Year for Snap-Together Furniture

Several converging factors make this year pivotal. First, the widespread adoption of generative design software has allowed engineers to iterate thousands of joint configurations digitally before physical prototyping. Second, sustainability mandates have pushed manufacturers toward mono-material construction—desks made from single, recyclable polymers or engineered wood products that can be formed with integrated fastening features. Finally, the post-pandemic hybrid work model has created unprecedented demand for furniture that can be reconfigured weekly without damaging components or degrading structural integrity.

Understanding Modular Desk Systems: A Primer

Before you click “add to cart,” it’s crucial to understand the underlying architecture of modular systems. Unlike traditional desks that arrive as a fixed configuration, true modular desks consist of interchangeable nodes, spans, and surface modules that can be assembled in multiple orientations. Think of it as a building system rather than a single product.

Key Components That Make Tool-Free Assembly Possible

The magic happens at the connection points. Look for desks featuring integrally molded dovetails on horizontal beams that slide into vertical legs with matching profiles. These systems often incorporate living hinges—flexible polymer sections that provide initial give during assembly then lock rigidly into place. Premium models use gravity-assisted wedge locks where the desk’s own weight tightens joints when properly seated. Understanding these mechanisms helps you evaluate whether a system is genuinely tool-free or just using hidden screws you’ll discover during disassembly.

Material Matters: What Your Desk Is Really Made Of

The material composition directly impacts everything from durability to environmental footprint. In 2026’s market, you’ll encounter three primary categories, each with distinct advantages for tool-free construction.

Engineered Wood vs. Solid Wood vs. Metal Frames

Engineered wood products like high-density fiberboard (HDF) with thermally fused laminate have become the sweet spot for snap-together desks. Their consistent density allows for precise CNC-routed joints that maintain tolerances within 0.1mm—critical for friction-fit connections. Solid wood, while aesthetically superior, expands and contracts with humidity, potentially loosening snap joints over time. Metal frames, typically aluminum extrusions, excel in leg structures where T-slot profiles accept injection-molded nylon connectors that click into place with audible feedback.

The Role of High-Performance Polymers in Snap-Fit Joints

Don’t overlook the humble plastic connector. Modern glass-filled nylon 66 and PEEK (polyetheretherketone) components can achieve tensile strengths exceeding 200 MPa while maintaining the flexibility needed for snap-fit engagement. These polymers are engineered with specific crystalline structures that resist creep—the slow deformation under constant load that causes wobbling in cheaper systems. When evaluating a desk, ask whether connectors are made from virgin or recycled polymer; the former typically maintains tolerances better over five-plus years of use.

The Anatomy of a Snap-Together Connection

Understanding what happens at the micro-level when you push two components together will make you a smarter shopper. It’s not just about whether it clicks—it’s about how it clicks and what keeps it from un-clicking when you lean on it.

Cam Locks, Dowels, and Beyond: Modern Fastening Innovations

Traditional cam locks required a screwdriver; 2026’s iterations use tool-less eccentric cams that rotate 90 degrees with a quarter-turn of your hand. These cams engage with precision-molded studs featuring undercut grooves that prevent pull-out forces up to 150 pounds per joint. Meanwhile, expandable dowels made from shape-memory polymers slightly compress during insertion, then expand to fill microscopic gaps in the receiving hole, creating a friction fit that actually strengthens over the first 72 hours as the polymer “sets.”

Weight Distribution and Structural Integrity Without Screws

Here’s where physics gets interesting. Tool-free desks rely on load path optimization—designing components so weight transfers through compression rather than tension or shear. When you place your monitor on the desk, force travels down through interlocking vertical ribs in the leg posts, which are wider at the base following a catenary curve principle. The absence of screws means no stress concentration points; instead, force disperses across entire contact surfaces. Ask manufacturers for finite element analysis (FEA) diagrams showing stress distribution under load—these reveal whether a design is truly engineered or just aesthetically minimal.

Ergonomic Considerations for Modular Desk Configurations

A desk that assembles easily but leaves you with repetitive strain injury isn’t a bargain—it’s a liability. The modular nature of these systems introduces unique ergonomic opportunities and challenges that fixed desks don’t face.

Height-Adjustable Modules and Biomechanical Optimization

2026’s standout systems offer segmented height adjustment where individual leg modules can be set to different elevations, creating subtle inclines that promote better wrist posture. Look for desks with biomechanical marker points—etched indicators at 28.5" (optimal for 5'6" users) and 30.25" (for 6'0" users) that align with elbow height when seated. Premium configurations include cantilevered keyboard trays that attach via the same snap system but can be repositioned without tools as your posture needs change throughout the day.

Cable Management Integration in Tool-Free Systems

Nothing kills the clean aesthetic of a snap-together desk faster than dangling cables. Modern systems integrate cable raceways directly into leg extrusions, with snap-on covers that blend seamlessly. Some advanced models feature inductive charging channels molded into the desktop surface, allowing you to power devices through the material itself. When evaluating options, check whether cable management components are also tool-free; some manufacturers cheat by requiring screws for these secondary elements.

Size and Scalability: Planning Your Workspace Evolution

The true value of modularity lies in future-proofing. Your needs today—single monitor, laptop, and notebook—might expand tomorrow to include dual 34" ultrawides, a streaming deck, and production equipment.

Starter Kits vs. Expansion Packs: Understanding Modular Growth

Most 2026 systems are sold as core nodes—basic L-shapes or straight desks—with expansion bays that attach via standardized interfaces. The key is verifying backward compatibility: will components you buy in 2027 fit your 2026 starter kit? Reputable manufacturers publish interface specifications guaranteeing dimensional stability for at least five product generations. Be wary of systems where expansion modules cost more than 60% of the original per-linear-foot price; this indicates proprietary lock-in rather than genuine modularity.

Surface Materials and Finish Durability

Your desk’s surface is where theory meets coffee rings, cat claws, and the abrasive bottom of your laptop. The assembly method affects finish options more than you might think.

Scratch Resistance, Heat Tolerance, and Longevity Testing

Tool-free assembly often means surfaces arrive as pre-laminated panels with edges already finished—no on-site trimming that could expose raw material. Look for multilayer nanocoatings that incorporate silicon carbide particles for scratch resistance while maintaining the flexibility needed for snap joints. For heat tolerance, check whether the surface has been tested to 150°C contact temperature without delamination—a critical spec if you use hot-plate coffee warmers or high-performance laptops that vent upward. Ask for Taber abrasion test results; quality surfaces should withstand 500+ cycles with minimal wear.

Technology Integration in 2026’s Modular Desks

The “smart desk” concept has matured from gimmicky app-controlled height adjustment to genuinely useful integration that respects the tool-free philosophy.

Built-In Wireless Charging and Cable-Free Power Solutions

Leading designs embed Qi charging coils directly under the surface laminate during manufacturing, creating seamless charging zones marked by subtle etched patterns. More impressive are conductive polymer strips running along desk edges, allowing you to snap-on modular power pods, LED light bars, or monitor arms that draw electricity through contact points—no cables to manage, no drilling required. These systems typically operate at 24V DC for safety, with a single transformer hidden in one leg.

IoT Connectivity and Smart Desk Features

While not strictly necessary for assembly, IoT integration in 2026 focuses on usage analytics that help you optimize your layout. Sensors in leg modules detect load distribution and can suggest repositioning heavy equipment to reduce stress on specific joints. Some systems sync with calendar apps, automatically adjusting attached monitor arms to standing height for scheduled video calls. The key is that all smart components must also snap on/off without tools; otherwise, they undermine the core value proposition.

Sustainability and Eco-Friendly Manufacturing

The environmental story behind tool-free desks is more nuanced than “no screws means less metal.” The entire lifecycle—from factory floor to eventual recycling—has been re-engineered.

Recyclable Materials and Carbon-Neutral Production

True sustainability means mono-material construction: desks made entirely from a single polymer or engineered wood type that can be shredded and reformed without separation. Look for closed-loop recycling programs where manufacturers accept returned components and reprocess them into new joints and panels. In 2026, several factories have achieved carbon neutrality through renewable energy and bio-based polymers derived from agricultural waste. Check for EPD (Environmental Product Declarations) that quantify carbon footprint per desk configuration, not just vague “eco-friendly” marketing.

The True Environmental Cost of Flat-Pack vs. Pre-Assembled

Here’s a counterintuitive insight: tool-free flat-pack desks often have a lower carbon footprint than pre-assembled units because they ship denser, reducing transportation emissions per unit volume. A disassembled desk might occupy 30% of a shipping container compared to a pre-built one, allowing three times more product moved per truckload. The key is ensuring packaging is also sustainable—avoid systems that use expanded polystyrene; instead, look for molded pulp inserts made from recycled cardboard that protect corners during transit.

Price Tiers and Value Proposition

Tool-free desks span from under $200 to over $2,000. Understanding what you’re paying for at each level prevents disappointment and helps you invest wisely.

Budget-Friendly Basics vs. Premium Modular Systems

Entry-level systems ($200-$500) typically use simpler cam-lock mechanisms with ABS plastic connectors and particleboard surfaces. They assemble easily but may develop slight wobble under 100+ pound loads and offer limited expansion options. Mid-tier desks ($500-$1,200) introduce aluminum leg extrusions, HDF cores, and glass-filled nylon connectors with genuine modularity. Premium systems ($1,200+) feature advanced polymers, integrated technology, mono-material construction for recycling, and lifetime interface guarantees that ensure future compatibility.

Hidden Costs: What Budget Desks Don’t Tell You

That $299 snap-together desk seems like a steal until you realize the cable management kit costs an extra $49, expansion connectors are $15 each, and the surface scratches so easily you’ll need a protective mat ($35) within six months. Worse, some budget systems use proprietary joint geometries that lock you into that brand’s ecosystem, limiting your ability to mix-and-match components from other manufacturers. Always calculate the total cost of ownership over five years, factoring in potential add-ons and replacement parts.

Common Pitfalls and How to Avoid Them

Even the best-engineered systems fail when fundamental principles are ignored. Knowing what typically goes wrong helps you spot design flaws before purchase.

Wobbling Issues, Weight Limits, and Surface Warping

Wobbling almost always stems from insufficient diagonal bracing or connectors that rely solely on friction without mechanical interlocks. Test for this by checking if leg modules include cross-bar integration points even if you don’t initially purchase the cross-bars. Weight limits should be specified per square foot and per joint; a desk rated for 200 pounds total might fail if that weight concentrates on a single corner. Surface warping occurs when moisture penetrates exposed edges; ensure your chosen system has fully encapsulated edges on all panels, not just the visible ones.

Installation Best Practices for Snap-Together Desks

The promise of “no tools” doesn’t mean “no thought.” Proper assembly technique significantly impacts long-term stability and your sanity during the process.

Floor Preparation and Assembly Sequencing

Start with a hard, level surface—carpet compresses unevenly and can induce stress on joints. Lay down a blanket or foam sheet to protect the desktop surface during assembly. The optimal sequence is legs first, then lateral supports, then surface panels; this allows you to verify squareness before committing weight. For L-shapes or U-shapes, assemble the primary section completely, then attach extensions. Never force a connection; if a joint doesn’t seat smoothly, check for packaging debris in the receiving slot rather than applying more pressure.

Maintenance and Longevity of Tool-Free Systems

A well-designed snap-together desk should last a decade, but only if you understand its unique maintenance requirements.

Reconfiguration Tips and Joint Preservation

Each disassembly/reassembly cycle microscopically wears connector surfaces. Limit full teardowns to once or twice per year; instead, learn to add modules in situ by temporarily relieving load on adjacent joints. Clean connectors annually with compressed air to remove abrasive dust, and apply a dry PTFE lubricant to moving cam surfaces if they become stiff. Never use liquid oils—they attract dirt and can degrade polymer connectors. When storing disassembled components, keep connectors covered with original protective film to prevent UV degradation, which makes them brittle.

Room-Specific Buying Strategies

The perfect modular desk for a corporate hot-desking floor differs dramatically from one suited to a bedroom content creation studio.

Home Offices, Gaming Setups, and Corporate Environments

For home offices, prioritize acoustic dampening—desks with hollow leg chambers can resonate and amplify keyboard clatter; look for foam-filled extrusions. Gaming setups demand exceptional weight capacity (triple monitor arms, full-tower PCs, streaming gear) and RGB integration through snap-on light modules. Corporate environments need standardized interface compliance for mixing components from approved vendors and anti-microbial surface treatments that remain effective after repeated cleaning with harsh disinfectants. Each scenario also has different aesthetic longevity concerns; corporate buyers should choose neutral designs that won’t look dated during the furniture’s 7-year depreciation cycle.

Frequently Asked Questions

How much weight can a snap-together desk realistically hold compared to a traditional screwed-together desk?

A well-engineered tool-free desk matches or exceeds traditional construction, typically supporting 150-300 pounds distributed load. The key is load distribution rather than absolute weight; snap systems excel at dispersing force across multiple interlocking surfaces, whereas screws create stress concentration points. Always check the manufacturer’s per-joint rating rather than just the total weight capacity.

Will the connections loosen over time if I frequently reconfigure my setup?

Quality systems are designed for 50+ assembly cycles without degradation. The secret is in the connector material: glass-filled nylon and PEEK polymers have “memory” that returns to original dimensions after deflection. However, budget ABS connectors may show wear after 10-15 cycles. Look for lifetime cycle ratings in the technical specifications.

Can I assemble these desks alone, or do I need a second person?

Most 2026 systems are designed for solo assembly, with components weighing under 40 pounds each. The exception is large L-shaped or U-shaped configurations where aligning multiple sections simultaneously benefits from a second pair of hands. Many manufacturers now include “solo assist” features like temporary support clips that hold components at 90 degrees while you secure them.

What happens if I lose a connector piece? Are replacements available?

Reputable brands maintain spare parts inventory for at least 10 years and offer individual connector packs for $5-$15. Before purchasing, verify the manufacturer has a dedicated parts portal and doesn’t require you to buy entire module replacements. Some premium systems even include 2-3 spare connectors in the original package.

Are tool-free desks stable enough for vigorous gaming or heavy typing?

Stability depends on diagonal bracing, not the fastening method. Look for systems with optional cross-supports that snap between legs, creating triangulation that eliminates lateral movement. Desks without cross-bracing may exhibit slight wobble during intense gaming sessions. The best systems have torsional rigidity ratings above 50 Nm/degree.

How do I know if a modular system is truly expandable or just marketing fluff?

Check for published interface specifications with dimensional drawings. True modular systems adhere to standards like MOD-STD-2026 (a new industry benchmark for connector compatibility). If the manufacturer can’t provide technical documentation showing how future components will attach, you’re likely looking at a closed ecosystem.

Can I mount monitor arms and other accessories to these desks?

Most quality systems include integrated mounting points with metal reinforcement plates beneath the surface. Avoid desks that require drilling for monitor arms—this defeats the purpose of tool-free design. Check the C-clamp compatibility depth (typically 2-3 inches) and whether grommet holes have snap-in covers that can be removed and reinstalled without damage.

Do snap-together desks work on carpeted floors?

They can, but with caveats. Heavy carpet compresses unevenly, inducing stress on joints. Use furniture coasters or reinforcing plates that distribute leg load across a larger area. Some 2026 models include adjustable carpet feet with wide, snap-on bases specifically for this scenario. For deep pile carpet, consider assembling the desk in place rather than moving it assembled, as twisting motions can stress connections.

Are these desks environmentally friendly if they’re made of plastic connectors?

It depends on the plastic. Bio-based polymers from renewable sources can have a lower carbon footprint than metal fasteners. Look for Cradle to Cradle Certified connectors and desks with mono-material construction that simplifies recycling. The overall environmental impact is often lower than traditional desks due to reduced shipping weight and elimination of metal fasteners that complicate end-of-life processing.

What should I do if a joint won’t snap together no matter how hard I push?

Stop immediately. Forced assembly damages the precise tolerances needed for a secure fit. First, verify you have the correct orientation—many connectors are keyed and only insert one way. Check for manufacturing flash (excess material) or packing debris in the slot. A gentle pass with fine-grit sandpaper on the male connector can resolve tolerance issues. If problems persist, contact support; quality manufacturers will replace out-of-spec components rather than have you modify them.